AmeraLabs XVN-50 3D Printing Resin

Crafted as the ultimate tool for resin 3D printing, XVN-50 resin is the versatile material you’ve been seeking. Engineered with balanced flexibility, stiffness, impact resistance, and tensile strength, it’s your adaptable solution for various applications. AmeraLabs developed this resin with properties frequently needed in 3D printing.

Key Features

- Impact resistant

- Compatible with most MSLA and DLP resin 3D printers

- Dimensionally accurate and stable

- Low odour

- Hard non-sticky surface

- Fast curing

Achieve precision and stability with AmeraLabs XVN-50 resin, ensuring dimensionally accurate resin prints. The optimal balance of stiffness and flexibility results in precise yet non-brittle 3D prints. Ideal for prototypes, robotic parts, engineering applications, snap-fit components, and other assembly-required end-use products.XVN-50 is crafted for efficiency on low-powered MSLA/LCD 3D printers with LED light sources emitting 365-420nm UV light. Compatible with both colour and monochrome LCD 3D printers such as Phrozen Sonic Mini 8K, Elegoo Saturn, and Anycubic M5. Additionally, it delivers excellent results on DLP 3D printers like Asiga, Elegoo Mars 4, and Anycubic Photon D2.

You can find recommended 3D printing settings for many 3D printers here: AmeraLabs resin settings. Following post-curing, XVN-50 prints have a non-sticky, touch-friendly finish. With a hard surface (82 shore D), the prints resists scratching. Non-brittle in nature, the supports are easily cut with a hobby knife. These 3D prints can be seamlessly sanded, drilled, tapped for threading, and painted. Carefully pigmented, XVN-50 resin is offered in a solid black colour.

Humidity and Chemical Resistance:]XVN-50 exhibits moisture resistance, with 3.12% water absorption over 24 hours (ASTM D570). This ensures minimal deformation or alteration in mechanical properties due to humidity or brief liquid exposure. Despite this, objects printed with XVN-50 are not recommended for prolonged contact with water, organic solvents, or other liquids.

For enhanced humidity and chemical resistance, explore AmeraLabs AMD-3 resin.

Printing Tips- For a successful print, AmeraLabs recommend:

- Level your build plate.

- If it’s your first print with this resin, print something small first like this calibration model.

- Find initial printing settings here: AmeraLabs resin settings.

- Use support column thickness of 1.5-2 mm and support tip thickness of 0.3-0.5 mm.

- Use attachment layer.

- Hollow your models.

- Use slower lift speeds. 5 mm/min for bottom layers, and 40-60 mm/min for normal layers.

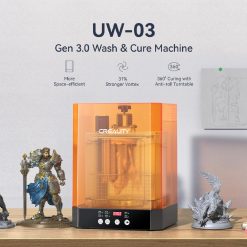

XVN-50 features a low-medium viscosity, which calls for cleaning to avoid resin entrapment in small model gaps. For Wash and Cure stations, immerse the print in IPA for 15 minutes, repeating as needed. If using standard IPA baths, follow this 4-step process:

- Submerge the print in IPA for 10 minutes.

- Actively swirl the IPA with the part for 1 minute.

- Allow the part to stand submerged for an additional 10 minutes, then change to fresh IPA.

- Actively swirl the bath for another 1 minute.

For ultrasonic cleaners, place the part in a sealed IPA container within the cleaner for 10 minutes, not exceeding 20 minutes. Avoid prolonged submersion (over 1 hour) to prevent model damage and preserve polymer properties. While it’s simpler to remove supports pre-post-curing, you can alternatively post-cure prints with supports intact for potential geometric improvements. Post-curing time, ranging from 5 minutes to 1 hour, depends on your curing station. Immediate post-curing after cleaning and drying is crucial. Achieving a non-sticky, resilient surface for XVN-50 prints requires thorough post-curing, rendering them resistant to scratching.