What Does Shore Hardness Mean?

What is Shore Hardness?

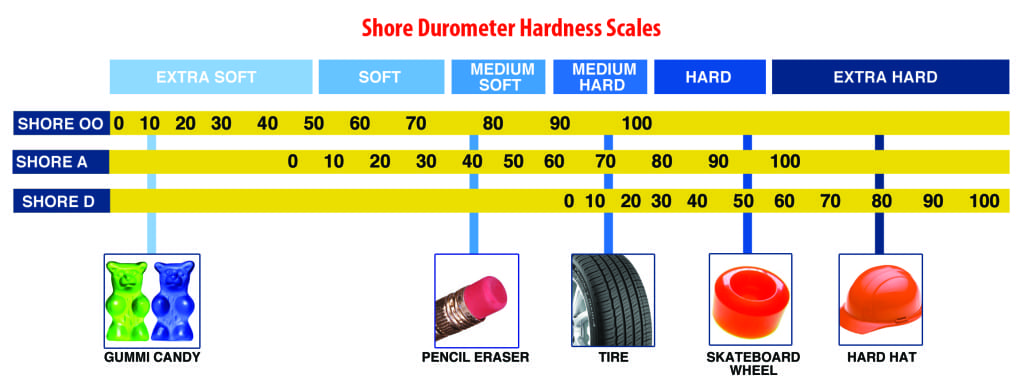

Shore Hardness is a measurement of the resistance a material has to indention. There are 3 distinct shore hardness scales for measuring the hardness of dissimilar materials. This spans from flexible rubbers to inflexible plastics, and super-soft gels. These scales were designed so that people can investigate these materials with a common point of reference.

Shore 00 Scale:

The Shore 00 Hardness Scale measures rubbers and gels that are very soft. For example, Platsil Gel 00 has a Shore 0030 hardness.

Shore A Scale:

The Shore A Hardness Scale measures the hardness of flexible mould rubbers that range in hardness from very soft and flexible, to medium and somewhat flexible, to hard with almost no flexibility at all. Some semi-rigid plastics can also be measured on the high end of the Shore A Scale. For example, Platsil FS 20 has a Shore 25A hardness.

Shore D Scale:

The Shore D Hardness Scale measures the hardness of hard rubbers, semi-rigid plastics and hard plastics. For example, Axson F40 has a Shore 84D hardness.

What is a Shore Durometer?

A Shore Durometer is a device for measuring the hardness of a material, typically of polymers, elastomers, and rubbers.

Higher numbers on this scale indicate a greater resistance to indentation and thus harder materials. Lower numbers indicate less resistance and softer materials.

Choice of Material

Shore Hardness becomes important when considering mould rubber choice when making a mould of your original. For example, you would not chose a rubber with a Shore Durometer of 70A to make a mould of a fragile model.

A 70A rubber (as hard as a car tyre) is stiff and would not offer enough flexibility to extract this model without breaking it. A better choice would be a Shore 30A rubber or softer. This would offer enough flexibility to easily extract the model.

TIP: Get to know your cured material with a sample you can feel with your hands. Some materials do contain a Shore Hardness indicator in their name.